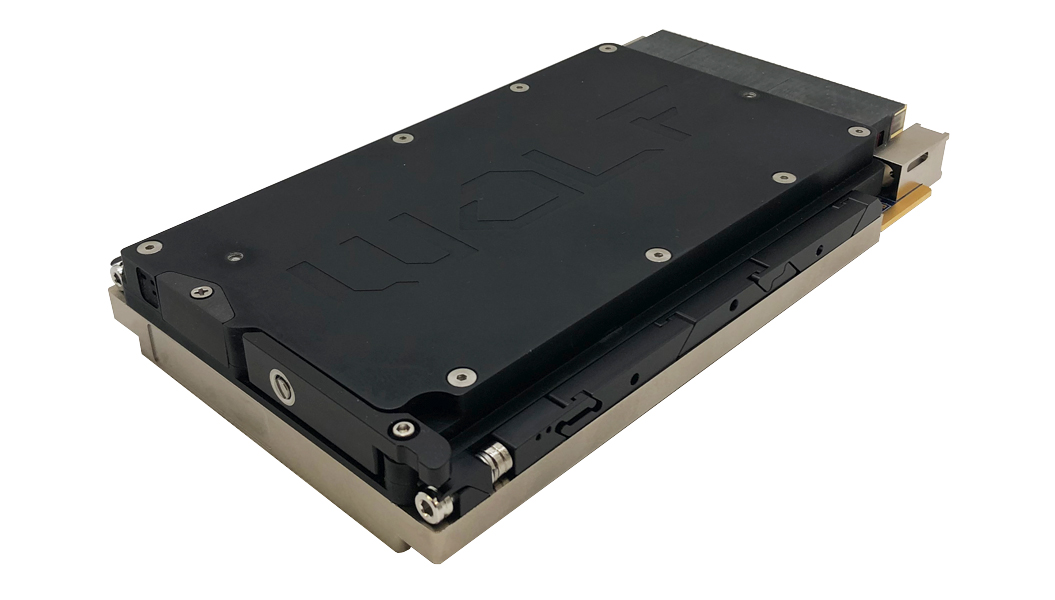

| Handles/Panels for VPX |

Elma’s VPX handles and panel solutions come in 1.0”, 0.85”, and 0.80” widths for the various card sizes of the architecture. The VPX specification calls for the handle to be slightly offset from typical IEEE handle/panel placement. The handles feature Elma’s two-step latching process and are highly ergonomic. Elma also offers long versions of its IEEE and low profile VPX handles for increased leverage.

Elma employs a two-step process for its VPX panels by anodizing the front of the panel and alodining the back and sides. By anodizing the front of the panel, it provides a scratch-resistant and non-conductive material. This is ideal for the front of the panel where unsightly scratches and abrasions are unacceptable. The back and sides of the panels are alodined (clear chromate conversion), which is conductive, but not scratch resistant. Other in-house services include silk-screening, painting, overlays, and assembly of handles and springs.

Elma also offers injector/ejector handles in IEEE, IEC, Telco, Long Telco, and Classic styles.