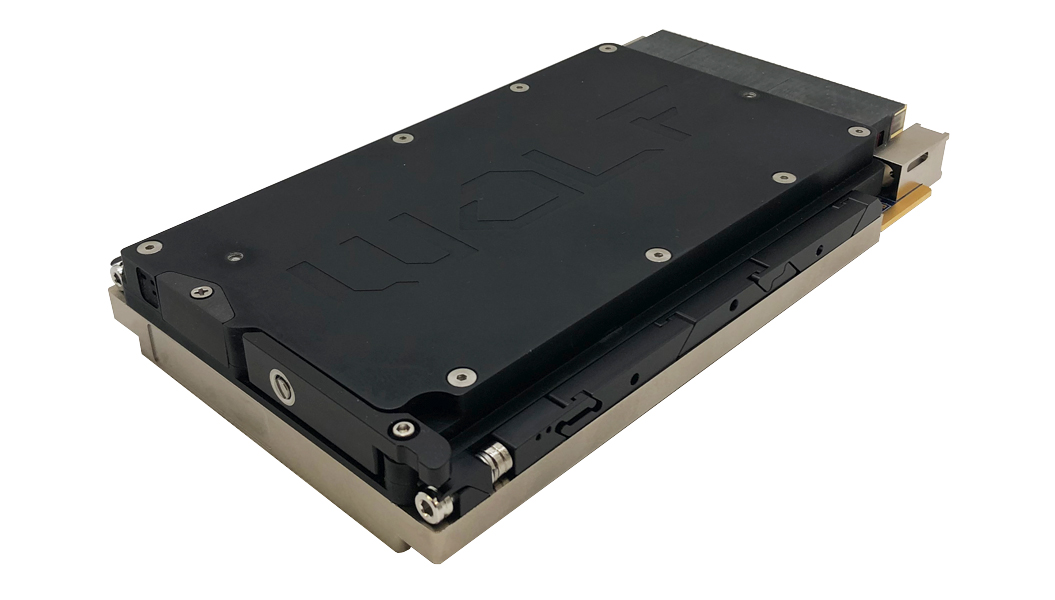

ASHBURN, VA – April 19, 2012 — Curtiss-Wright Controls Defense Solutions (CWCDS), a business group of Curtiss-Wright Controls, has introduced a new rugged chassis designed to support a development-to-deployment approach that reduces risk, schedule, and cost. The new D2D™ ¾ ATR, a 6-slot ¾ ATR-style forced air/conduction cooled chassis, eases the design of 3U OpenVPX™-based systems by enabling the system integrator to use the same enclosure, via simple configuration upgrades, throughout the complete program lifecycle, from development to demonstration and all the way to deployment. The D2D ¾ ATR chassis is the newest member of CWCDS’s Hybricon® family of advanced COTS electronic packaging solutions.

“Our new D2D ¾ ATR chassis eases and speeds system development by providing a single, cost-effective approach to integration, from the lab to the field, using the very same chassis at every phase of the application’s evolution,” said Lynn Bamford, senior vice president and general manager of Curtiss-Wright Controls Defense Solutions group. “This single platform for development, demonstration and deployment cuts design risk and boosts reliability.”

The rugged D2D ¾ ATR enclosure supports up to 6 slots of 3U 1.0″ pitch payload OpenVPX cards. The D2D ¾ ATR simplifies the integration process by providing a single enclosure that can be used equally well for in-lab development and fielded deployment. It is ideal for demanding SWAP-C constrained military, aerospace and first responder applications.

The D2D ¾ ATR enables system designers to commence development with a COTS Lab configuration chassis version using rugged conduction cooled payload and upgrade the enclosure as needed for demonstration and deployment stages:

Development version (lab only):

· Standard backplane using I/O cabling

· Chassis “bottom hat” and I/O cabling

· Chassis “top hat” if needed for module faceplate I/O cabling such as fiber optics and RF coax

· Connections for external power supply

· Industrial grade fans

· Significantly reduced up-front cost and lead time for chassis

Demonstration upgrade:

· Internal cabled power supply.

Rugged deployed upgrade:

· Replaces standard backplane and I/O cables with custom backplane and I/O panel with application-specific I/O signals

· Removes “bottom hat”

· Upgrades power supply to internal MIL grade power supply that plugs into the backplane

· Upgrade to MIL grade fans for extended temperature and shock/vibration

The deployment version of the D2D ¾ ATR chassis measures 7.62” high, 7.50” wide, and 12.61″ deep (without optional fan assembly) and weighs 13.7 lbs (6.2 kg) without fan assembly.

D2D ¾ ATR Performance Features:

· OpenVPX REDI designed to the latest ANSI/VITA 65, ANSI/VITA 46.0, ANSI/VITA 48.2, VITA 46.3-VDSTU, VITA 46.4-VDSTU, VITA 46.6-VDSTU, VITA 46.7-VDSTU, and VITA 68 (draft)

· 3U 6-slot 1” pitch backplane, compatible with rear transition cables

· Add-on “top hat” to support I/O from module and mezzanine faceplates (e.g. fiber optics, RF coax)

· “Bottom hat” for development/demonstration to support I/O cabling or custom backplane connectivity using backplane RTM connectors for development and demonstration

· Supports standard 6-slot OpenVPX 1″ pitch or custom backplanes

· Supports six (6) 3U 1.0″ pitch VPX-REDI slots per ANSI/VITA 65 and ANSI/VITA 48.2

· Two (2) power supply slots support a total of 200W or 400W, 28 VDC input power supply(s) compliant to MIL-STD-704F and MIL-STD-1275B

· Supports industrial grade or MIL grade rear fan assemblies (option), or can accept cooling air provided by the platform

· Curtiss-Wright’s intelligent Power & Control Module (PCM) for Ethernet/SNMP chassis monitoring/BIST (option)

· Ideal for IRAD projects

· Eliminates the need to procure separate air-cooled payload for development where the deployed version is conduction cooled

· Modified COTS configurations and system integration services available.

Please contact factory for price and availability. For additional product information on the D2D ¾ ATR and to download the factsheets, please visit: www.cwcelectronicsystems.com/rme_enclosures.htm[…]

Sales & Editorial Contacts

For editorial information regarding Curtiss-Wright Controls Defense Solutions products or services, contact John Wranovics, public relations director, Curtiss-Wright Controls, Tel: (925) 640-6402; email: [email protected].

Sales inquiries: Please forward all Sales and reader service inquiries to Maria Antal, Curtiss-Wright Controls Defense Solutions, Tel: (978) 952-2017; email: [email protected].

About Curtiss-Wright Controls Defense Solutions

Curtiss-Wright Controls Defense Solutions (CWCDS) is a long established technology leader in the development of rugged electronic modules and systems for defense applications. CWCDS serves as a technology and integration partner to its customers, providing a full range of advanced, highly engineered solutions from modular open systems approaches to fully custom optimized solutions. Our unmatched capabilities and product breadth span from industry standard based COTS modules to complete electronic subsystems. The company’s modules and systems are currently deployed in a wide range of demanding defense & aerospace applications including C4ISR systems, unmanned subsystems, mission computing, fire control, turret stabilization, and recording & storage solutions. Additionally, the company’s broad engineering capabilities combine systems, software, electrical, and mechanical design expertise with comprehensive program management and a broad range of life-cycle support services. For more information visit www.curtisswrightds.com.

About Curtiss-Wright Controls, Inc.

Headquartered in Charlotte, N.C., Curtiss-Wright Controls is the motion control segment of Curtiss-Wright Corporation (NYSE: CW). With manufacturing facilities around the world, Curtiss-Wright Controls is a leading technology-based organization providing niche motion control products, subsystems and services internationally for the aerospace and defense markets. For more information, visit www.cwcontrols.com.