| Curtiss-Wright Launches Groundbreaking Fabric40™ Next-Generation Fabric Program to Increase Bandwidth of Embedded Military Systems – See more at: http://www.curtisswrightds.com/media-center/press-release/curtiss-wright_launches_groundbreaking_fabric40_next-generation_fabric_program.html#sthash.xhZ7IQ0q.dpuf |

ASHBURN, VA – July 17, 2013 — Curtiss-Wright Controls Defense Solutions, a business group of Curtiss-Wright Controls, today announced the industry’s first initiative to increase the interconnect speeds of High Performance Embedded Computing (HPEC) systems to 40 Gbps with the launch of its new Fabric40™ Program, which brings support for the newest generation of high-speed serial fabrics, including QDR Infiniband® and 40 Gigabit Ethernet (40 GbE) to the company’s comprehensive family of end-to-end COTS system solutions. Designed for the most demanding defense and aerospace rugged deployed applications, HPEC systems are focused on next-generation radar and signal processing platforms and C4ISR applications. Curtiss-Wright’s new Fabric40 Program significantly reduces engineering risks and integration time when bringing leading-edge HPEC technology to market.

“Today, 40 Gbps fabrics, such as Infiniband and 40 Gigabit Ethernet, deliver the market’s best price/performance/power mix for open system solutions,” said Lynn Bamford, senior vice president and general manager of Curtiss-Wright Controls Defense Solutions. “Curtiss-Wright continues to lead the industry in bringing the highest performance COTS products to market, and with our new Fabric40 Program we are the first to offer complete end-to-end next-generation 40 Gbps solutions for C4ISR and HPEC computing systems.”

Industry’s First End-to-End 40 Gbps Solutions

The Fabric40 Program establishes the industry’s first complete end-to-end approach to integrating the latest high-speed fabrics into customer applications. In addition to enabling individual system components with 40 Gbps high-speed interconnects, the Fabric40 Program also ensures that all aspects of this new data fabric technology are optimally configured to work together, which greatly reduces our customers’ integration risks and development time.

Curtiss-Wright Fabric40 products are the industry’s first to offer end-to-end support for both

10 Gbps and 40 Gbps Ethernet fabrics, and support the full range of Infiniband fabrics including Infiniband SDR (10 Gbps), DDR (20 Gbps), and both QDR and FDR-10 (40 Gbps) data rates, which effectively doubles the interconnect rates currently supported by Curtiss-Wright’s already industry-leading 20 Gbps interconnect-based products. To ensure that processing engines and CPUs are not burdened by high-speed data transfers, Fabric40 products support Remote Direct Memory Access (RDMA) technology in both Ethernet and Infiniband modes. The complete Fabric40 ecosystem also includes middleware software enablement such as IPC and OFED/MPI interfaces, which are all optimized to support next-generation 40 Gbps systems.

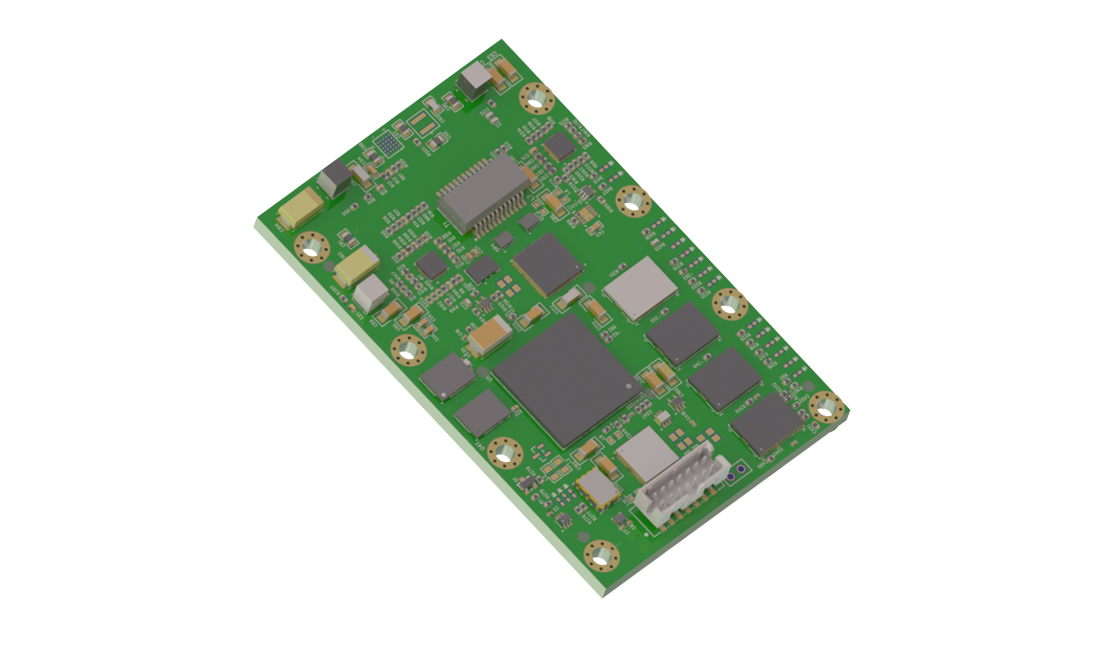

The First Fabric40 Product: CHAMP-AV9

The first product featured in the Fabric40 program is the recently introduced CHAMP-AV9, the industry’s first rugged, high performance OpenVPX™ (VITA 65) DSP (digital signal processing) engine based on a pair of the latest 4th generation Intel® CoreTM i7-4700EQ Haswell processors. This Fabric40 enabled product will significantly improve the performance of open architecture

rugged embedded systems, eliminating data bottlenecks that impede optimal performance, by effectively doubling system I/O bandwidth from the previous ceiling of 20 Gbps to 40 Gbps, today’s new standard for the highest performance..

“We are proud to be the first leading COTS vendor to establish an initiative that brings the advantages of 40 Gbps fabrics to our defense and aerospace customers’ most demanding HPEC requirements,” added Ms. Bamford. “Our Fabric40 Program significantly reduces the risks our customers will face when adopting this bottleneck-eliminating high throughput processing technology.”

Signal Integrity and End-to-End Interoperability

Today, system integrators must address the issue of Signal Integrity when designing high-performance embedded systems with next-generation 40 Gbps interconnects. Curtiss-Wright has developed its entire line of Fabric40 products with highly optimized Signal Integrity design rules to ensure that high-speed signals are not compromised when interconnecting from board to board through backplanes. Curtiss-Wright will provide a complete Fabric40 system solution, including all of the individual system components such as Single Board Computers (SBC), DSP and FPGA engines, GPGPU processors, network switches and backplanes, so that system integrators can be confident their entire next-generation system will work together reliably from end-to-end.

Multi-Protocol Support on Curtiss-Wright Fabric40 Products

Until now, customers have been locked into using a single technology fabric in their HPEC system designs. Today, thanks to higher-level hardware functionality built into Curtiss-Wright’s latest Fabric40 enabled modules, support for interconnect fabrics is “agnostic”. This provides customers with the option, for the first time, to select either 10 Gbps or 40 Gbps Ethernet or the 10 Gbps / 20 Gbps / 40 Gbps Infiniband protocols that best suit their particular application’s requirements.

Complete Fabric40 End-to-End Solutions

Curtiss-Wright will soon announce additional products supporting the Fabric40 Program, including SBCs, network switching fabrics, and OpenVPX backplanes qualified for next-generation data rates. With Fabric40 solutions for every element of the sensor processing technology chain, from the ADC/DAC analog conversion located next to the platform antenna/sensors to FPGA, DSP, GPGPU and SBC processing elements, Curtiss-Wright is uniquely positioned to provide the industry’s only complete end-to-end 40 Gbps ecosystem solutions.

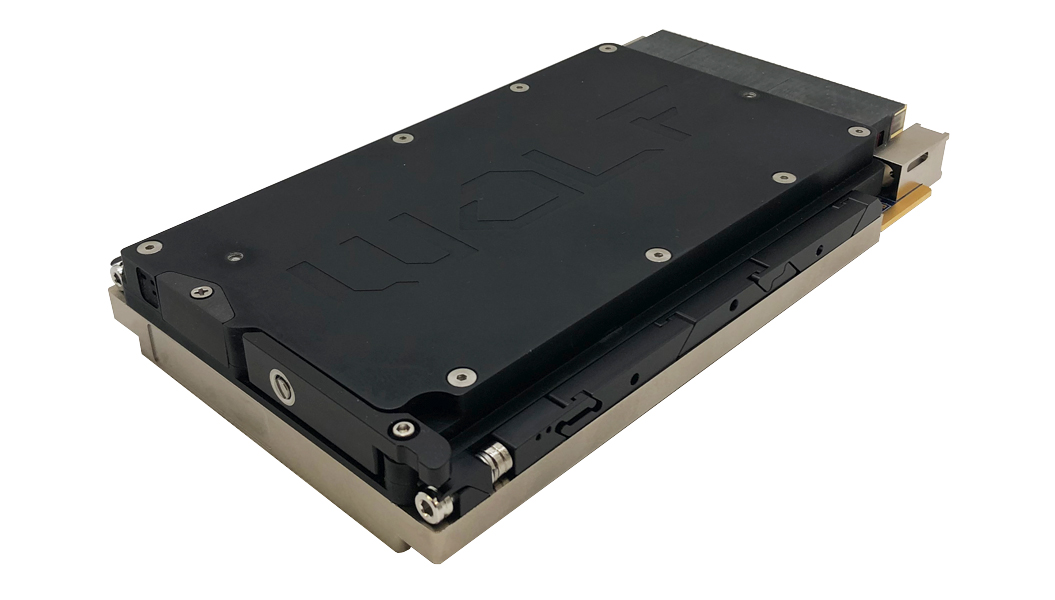

About the CHAMP-AV9

The CHAMP-AV9 is specifically designed to operate in extreme environmental conditions for rugged, deployed applications at the highest possible performance level. Using the enhanced Intel® Advanced Vector Extensions (Intel® AVX) 2.0 instruction set, the CHAMP-AV9 offers

664 GFLOPS per board, not including the on-chip GPGPU numerical co-processors, to deliver more than double the performance of previous DSP solutions. CHAMP-AV9 is also the first OpenVPX DSP engine to utilize a 40 Gbps Ethernet or Infiniband data plane fabric, providing

14 GByte/sec full duplex throughput with RDMA to support scalable, distributed, real-time computing. With full VxWorks® and Linux support, as well as accompanying middleware, libraries and tools, the CHAMP-AV9 provides a seamless migration path for both existing CHAMP-AV DSP applications and large, distributed node HPEC systems. With CHAMP-AV9,

Curtiss-Wright maintains performance leadership in COTS DSP for the industry’s harshest environments.

The board’s 4th generation Intel® Core™ i7 Haswell processors contain substantial improvements over previous generations:

• Double the CPU floating-point performance with a fused multiply-add AVX instruction

• Ability to load two and store one operand per clock

• Double the L1 and L2 cache bandwidth vs. 3rd generation Intel® Core™ processors

• 2.6 GHz CPU clock

The CHAMP-AV9 engine has been upgraded to DDR3-1600 and rugged implementations of the module will incorporate thermal management solutions that eliminate CPU throttling at our benchmark 71C degree air-cooled and conduction cooled 85C degree card-edge environments. This contrasts with alternative solutions in which the CPUs throttle severely or are simply unable to operate at an 85C degree card-edge.

CHAMP-AV9 Key Features:

• Extreme numerical processing for DSP and general purpose applications

• 6U OpenVPX compliant

• Two quad-core Intel® Core™i7-4700EQ Haswell processors

• Intel AVX 2.0 256-bit floating point vector unit

• 664 CPU GFLOPs (332 per CPU) peak computing performance

• On-chip graphics execution units for additional numerical processing

• 8 Gbytes DDR3 SDRAM (25 GB/s) with ECC per processor (16 Gbytes total)

• Four (4) 40 Gbps Ethernet/Infiniband® Data Plane interfaces

• 32-lane Gen3 PCI Express Expansion Plane interface supporting four (4) 8x and two (2) 16x ports

• Power management features

• VxWorks® BSP and Linux LSP

• 6U OpenVPX compliant

• Non-throttling rugged air-cooled and conduction-cooled versions

Extensive Software Support

The CHAMP-AV9 is supported with an extensive suite of software including support for Wind River® VxWorks® and Linux operating environments. Additional software support includes Curtiss-Wright’s Inter-processor communications (IPC), OFED/MPI, Continuum™ Vector Intel AVX 2.0-optimized signal processing library and Continuum™ Insights Graphical Management and Debug tool.

For more information on the CHAMP-AV9 click here.

Sales & Editorial Contacts

For editorial information regarding Curtiss-Wright Controls Defense Solutions products or services, contact John Wranovics, public relations director, Curtiss-Wright Controls, Tel: (925) 640-6402; Email: [email protected].

Sales inquiries: Please forward all Sales and reader service inquiries to Jerri-Lynne Charbonneau, Curtiss-Wright Controls Defense Solutions, Tel: (613) 254-5112; Fax: (613) 599-7777; e-mail: [email protected]. Curtiss-Wright Controls Defense Solutions, Tel: (978) 952-2017.

For additional information on Curtiss-Wright Controls Defense Solutions please visit: www.curtisswrightds.com.

About Curtiss-Wright Controls Defense Solutions

Curtiss-Wright Controls Defense Solutions is a long established technology leader in the development of rugged electronic modules and systems for defense applications. The Defense Solutions group serves as a technology and integration partner to its customers, providing a full range of advanced, highly engineered solutions from modular open systems approaches to fully custom optimized solutions. Our unmatched capabilities and product breadth span from industry standard based COTS modules to complete electronic subsystems. The company’s modules and systems are currently deployed in a wide range of demanding defense & aerospace applications including C4ISR systems, unmanned subsystems, mission computing, fire control, turret stabilization, and recording & storage solutions. Additionally, the company’s broad engineering capabilities combine systems, software, electrical, and mechanical design expertise with comprehensive program management and a broad range of life-cycle support services. For more information visit www.curtisswrightds.com.

About Curtiss-Wright Controls, Inc.

Headquartered in Charlotte, NC, Curtiss-Wright Controls is the Motion Control segment of Curtiss-Wright Corporation. With manufacturing facilities around the world, Curtiss-Wright Controls is a leading technology-based organization providing niche motion control products, subsystems and services internationally for the aerospace and defense markets. For more information, visit www.cwcontrols.com.