Obsolescence is often hailed as “the dark side of COTS procurement” for the U.S. Department of Defense (DoD). Military platforms – many of which are expected to survive for at least 50 years – are becoming dependent upon commercial technology as a way to decrease costs.

But there are serious downsides to tapping COTS components that can become obsolete within 18 months – particularly when it comes to managing obsolescence issues. It poses numerous challenges for integrators, embedded suppliers, distributors, and aftermarket suppliers alike.

Can long life cycle military platforms coexist with COTS?

How are long life cycle military platforms able to coexist with COTS components that can become obsolete within 18 months?

This reality is a significant challenge, according to Christopher Bruns, director of component application engineering for Rockwell Collins in Cedar Rapids, Iowa. To deal with it, the company is “aligning itself with preferred suppliers that provide extended product life cycles,” he says. “And we augment this with product road maps that include block update strategies to allow us to minimize the impact of obsolescence by making shorter duration buys when components go ‘end of life.’”

Flexibility is another key piece of coexistence: “Customers want the flexibility to choose what’s right for their program,” says Richard Kirk, product manager for Abaco Systems in Huntsville, Alabama. “The first approach is committing to making a product available for a minimum of seven years. Then we can offer long-term support services, which means that the product is available as long as the customer needs it.”

An alternative is to “design a series of ‘technology-insertion’ steps so customers can slot in new products with minimum integration effort,” Kirk adds. “It will have the same pinout and specific new hardware features can be masked by the software.”

Customers who bought a single-board computer (SBC) from Abaco in 1998 can obtain “essentially the same board nearly 20 years later, but with significantly more performance,” Kirk points out. “This type of technology insertion strategy is popular with many customers because it’s common for military platform capabilities to be upgraded during their lifetime. This is something that Abaco’s customers factor in at a platform’s outset, and our strategy is to allow them to do that with minimum cost and disruption – in effect a straight swap.”

Not everyone believes COTS belong within military platforms, however. “The biggest problem is that the military is using commercial products, which aren’t designed for longevity,” says Dale Lillard, president of Lansdale Semiconductor in Tempe, Arizona. “Roughly one percent of semiconductor revenue comes from the military, so they’re not exactly driving semiconductor manufacturers to keep producing their products. And life cycles are much shorter now, so the aftermarket is having a difficult time maintaining newer technologies.”

Another issue is that “during the past 18 months, we’ve seen significant delays within our airspace in the Americas due to glitches and shutdowns of airline systems,” says Rich Fitzgerald, vice president of business operations for Avnet in Phoenix, Arizona. “The suggestion that perhaps these glitches are not simple outages but the result of using COTS solutions in complex secured networks is concerning … and a problem that must be addressed. Government agencies, designers, OEMs, distributors, and integrators can’t simply put their heads in the sand. Everyone is accountable for the actions and outcomes of designing COTS solutions into technology, and the military space isn’t a place for it to play a significant role.”

Fitzgerald acknowledges a need to reduce overall costs, but points out that oversight – in which checks and balances are required – could use some improvement. “Bills of materials, labor, overhead, and costs must all be managed,” he elaborates. “Private business could never get away with the lack of discipline and controls that our government shows in its oversight of costs. This is driving the discussion of going to COTS and, frankly, it’s a root cause of the issue.”

Component and integration designers “are increasingly moving toward COTS in their designs, but with proper planning and requirements – including life cycle requirements – they can be designed into military solutions,” Fitzgerald continues.

“Inventory is a ‘dirty word,’ because companies don’t want those costs on their balance sheet. Avnet manages these services and can play a significant role in end-of-life (EOL), life cycle management, and EOL buys to protect our government agencies and their contractors. This involves serialization management tracking, buying lifetime buys for such components, working closely with our supplier partners and customers, as well as mitigating parts so that ‘tin whiskers’ won’t create issues with ROHS (Restriction of Hazardous Substances) parts.”

Supply-chain/risk-management challenge

Obsolescence is a huge supply-chain challenge, which is essentially risk management.

“It’s very much about risk management and understanding the supply chain,” says Abaco’s Kirk. “The organizations with whom we work are anxious to mitigate risk throughout the program life cycle – from initial concept through development and testing to deployment. They want to eliminate or at least minimize the impact of risk, whether it’s to on-time delivery or cost overrun, and also the risk and impact of component obsolescence is something relatively easy to do.”

From Avnet’s perspective, “inventory is an asset, not a liability, and provides critical counsel to the military agencies and their primes,” Fitzgerald says. “Our approach is to look at requirements and then design upfront solutions that are managed throughout the life cycle so agencies aren’t surprised by obsolescence.”

Avoiding obsolescence management missteps

Are COTS vendors who are new to the military market making avoidable obsolescence management mistakes?

“When COTS suppliers obsolete a product, it’s extremely important for them to provide a next-generation device that will drop into our designs and that they notify us prior to discontinuance,” says Rockwell Collins’ Bruns. “The two primary issues we’ve seen are that some suppliers are unable to provide drop-ins, or when they do we find subtle differences that prevent us from being able to use them.”

Avnet’s Fitzgerald says he believes that obsolescence management for COTS providers is “counterproductive” because they’re “focusing on reducing costs, high rates of flexibility and change, as well as ensuring inventory is available in the channel. The world is moving to the Internet of Things, and 70 percent of the world’s market is now focused on COTS solutions, for which clients increasingly lead with software and cloud solutions – leaving the hardware to COTS and agnostic. This is critical for companies who have zero interest in operationalizing their business.”

Companies today “are set up with many software engineers, and one within their operations,” Fitzgerald continues. “These companies rely heavily on supply chain partners to manage end-to-end solutions – including inventory. The value is clearly software. Military solutions with long lead times and specific market requirements with minimal change allowable and higher mean-time-between-failure (MTBF) requirements don’t play well within the market. COTS may play a bigger role, but when it comes protecting our military, my recommendation is do not play with COTS.”

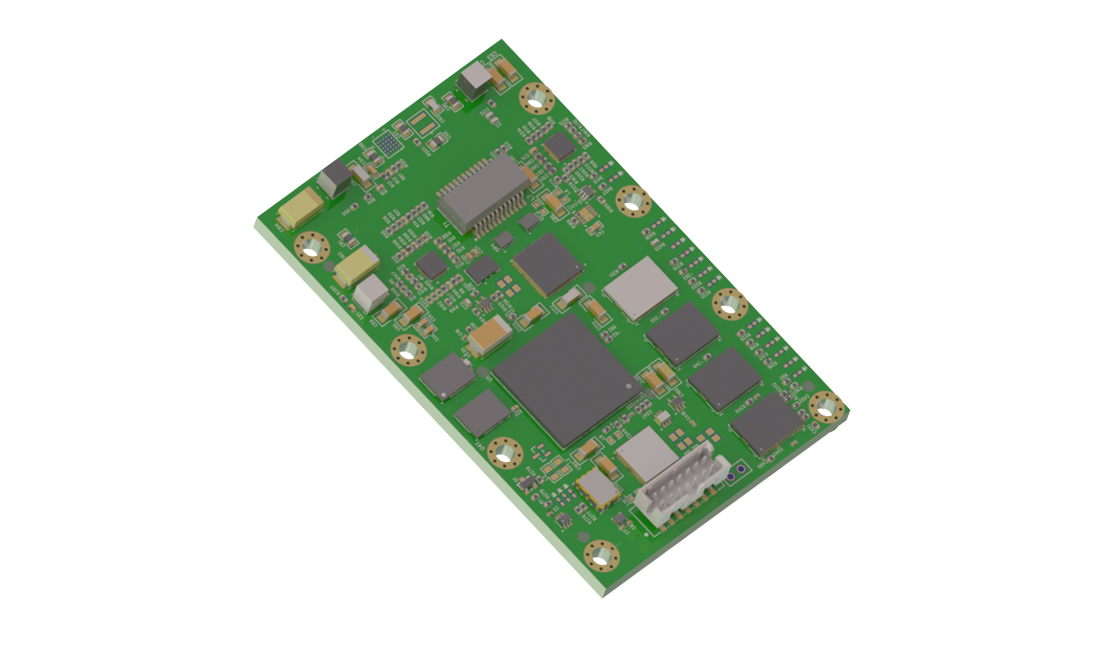

The biggest mistake for COTS vendors or newcomers to the military market would be “not having a program in place to offer long-term support and obsolescence management,” according to Abaco’s Kirk. A COTS product offered by Abaco is the PPC11A. Introduced earlier this year, the board is form, fit, and function compatible with the PPC4A, introduced in 1998, providing a straightforward technology insertion. (Figure 1.)

Current DoD procurement environment

Is the current DoD procurement environment, in which the government largely places the burden for research and development (R&D) investment on the integrators, making obsolescence and product life cycle management more challenging? Yes and no, but mostly yes.

“You can buy a component online with lot control and serialization and ship it within a day,” says Avnet’s Fitzgerald. “But dealing with government agencies requires a significant amount of scrutiny – some of which is required, yet is unnecessary for other areas. Avnet counsels government agencies by getting inside and in front of these challenges to reduce the overall end-to-end supply chain.”

Abaco’s customers “increasingly prefer to extend existing programs rather than start a new one,” points out Kirk. “This makes a lot of sense because startup costs for new programs can be huge.”

For customers who factor in extended programs from the outset, “the cost of providing extended support becomes part of the negotiation because they’re trying to minimize their overall cost,” he adds. “This, in turn, can shift some of the cost to the supplier.

“Recently, for example, one of Abaco’s customers wanted to extend a program for as long as five years for an eight-figure investment, but the condition of placing the order was that the chosen supplier would meet him halfway on the cost of long-term support. At the end of the day, it’s a business judgment call we’re asked to make. Customers recognize the importance of long-term support – and while it can make selling the concept easier, negotiations can become more complex.”