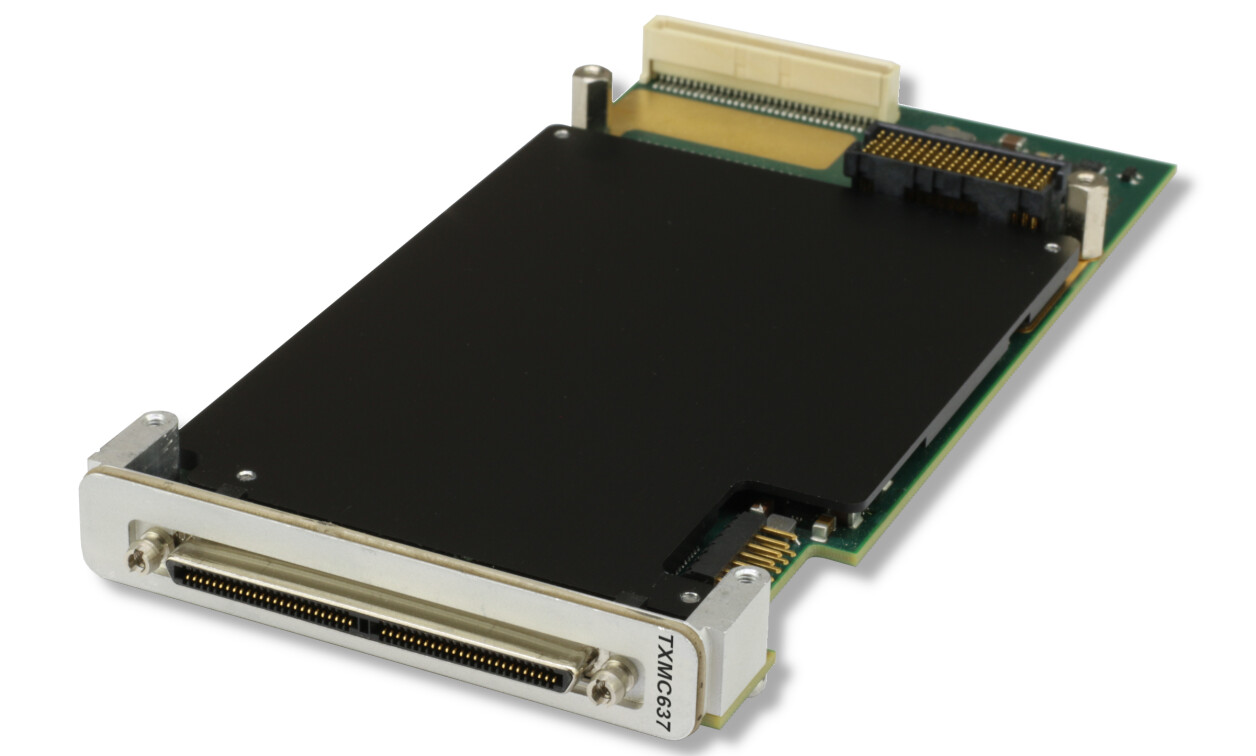

The VITA 71 “Rugged Mezzanine” standard will define the next-generation mezzanine cards that will allow products to be developed with electrical interfaces supporting higher-power, -speed, and performance applications. The need for this standard has become increasingly evident in the markets that VITA serves, as requirements intensify for a standardized mezzanine solution that supports the protocols, power requirements, physical interfaces, and thermal management technologies of future mezzanine cards while optimizing system Size, Weight, and Power (SWaP). The VITA 71 Working Group comprises more than 20 companies including board, system, and connector vendors and large prime contractors.

The scope of the VITA 71 Working Group is to define a groundbreaking mezzanine standard to replace the existing PMC and XMC standards. Whereas the migration from PMC to XMC was evolutionary, VITA 71 will be revolutionary. It will begin with a clean slate rather than being burdened with support for older mezzanine standards and will deliver denser processing solutions in lower weights that can be cooled more efficiently. VITA 71 will support:

- Next-generation multi-Gigabaud signaling rates (targeting up to 12+ Gbaud)

- Convection and conduction cooling

- Module front-panel and backplane connector I/O interfaces

- User-defined I/O

- System management

VITA 71 will optimize:

- Mezzanine and carrier board real estate utilization

- Power system distribution

- Mezzanine and carrier board cooling capabilities with support for convection and conduction cooling

- Allocation of pins, leveraging OpenVPX (VITA 65) Slot Profiles experience for uses such as management and fabric connection to the carrier card and user I/O to the backplane

Currently, PMC and XMC connectors are not rated for operation at the next-generation baud rates, for example >5 Gbaud, and they require significant real estate on the carrier and the mezzanine cards. The PMC/XMC sites do not bound power consumption beyond pin limits or provide adequate guidance or mechanisms for appropriate thermal management of the site. Additionally, the PMC/XMC sites require up to six unique voltage rails if there is a PMC/XMC site and support 3.3V_AUX as a separate rail. These and other factors – including the integration of more processing power and capabilities per square inch, and the need to locate sensor input closer to processors in smaller deployed systems – underscore the need for a revolutionary standard.

VITA 71 standard’s road map

Today, rules are bent and a mezzanine/motherboard pair is often customized to optimize the pair for increased power or thermal performance, moving away from existing standards and creating interoperability challenges even for the same vendor. The VITA 71 standard will address this and deliver better interoperability between mezzanine and carrier vendors. It will provide increased interface speeds as well as thermal and power capacity, which will enable higher-speed processing capabilities on a mezzanine and higher-performance I/O in a SWaP-optimized setting.

With the VITA 71 standard, prime contractors will have the flexibility to change vendors as needed with fewer thermal and mechanical interoperability concerns, aligning with customers’ goals of modeling upgrades and executing shorter design cycles.

VITA 71 progress

The VITA 71 Working Group was established last January. The first draft of the standard is expected to be complete by January 2011. Once published, it is expected that this standard will generate revisions in other VITA standards such as VITA 65, OpenVPX; VITA 46.11, VPX: System Management; and VITA 49, VITA Radio Transport (VRT).