VME: Can you tell us a bit about what Emerson provides, generally speaking, and to which industries?

DOYLE: Emerson Network Power’s Embedded Computing business offers integrated hardware and software, including application-ready platforms, enclosures, motherboards, blades and modules, and enabling software. We also offer professional services to help customers minimize design time, provide resources and training for deploying our technologies, and provide long-term support – including assistance transitioning from one product generation to the next.

Open standards and interoperability are at the heart of everything we do. We maintain a very strong position in the telecommunications industry and are rapidly building our presence in the military, aerospace, government, medical, automation, and industrial markets.

VME: About 2.5 years ago, Emerson acquired Motorola’s Embedded Communications Computing (ECC) business. Is the Motorola-to-Emerson transition complete?

DOYLE: Yes, the transition is complete. Our goals have been to combine the best elements of all the companies that are in the Embedded Communications Computing business’ DNA and to stay true to the qualities that our customers valued most. If you look back at our lineage, it includes names like Blue Wave, Hurikon, Mizar, Pro Log, Force Computer, and, of course, Motorola. It’s these companies, and people, under the guidance of a solid management team, that now make up the Emerson Embedded compute group.

I think that our strengths now include anticipating customer needs by listening to our customers and also speaking directly to end users. The MAG/military team is always looking for opportunities to sit with soldiers and front-line commanders to ask what they need in the field and what could we do better to help them. So it’s not just about providing innovative technologies – it’s about working as one entity to leverage what’s great and doing it better each day. That process is what the Motorola-to-Emerson transition has been about.

VME: What philosophical or focal point adjustments were made because of the acquisition? For example, wasn’t Motorola focused more on VME, while Emerson Network Power was and is more focused on telecom apps such as MicroTCA and AdvancedTCA?

DOYLE: We recognized going into this that there was great synergy between the two companies in technology and industry focus. Motorola had one of the longest histories with VME in the embedded computing market. Several years prior to the acquisition, Motorola chose to broaden the company’s position by adopting new technologies – including ATCA, which is an Emerson strength – to offer customers more technologies for multiple markets.

As you might expect, we aim to continue ATCA and VME technology development as key focal points of the new organization. And while ATCA remains the leading path for telecom customers, ATCA is now being considered for applications in industries as diverse as military communications including shelter-based and deployed networking.

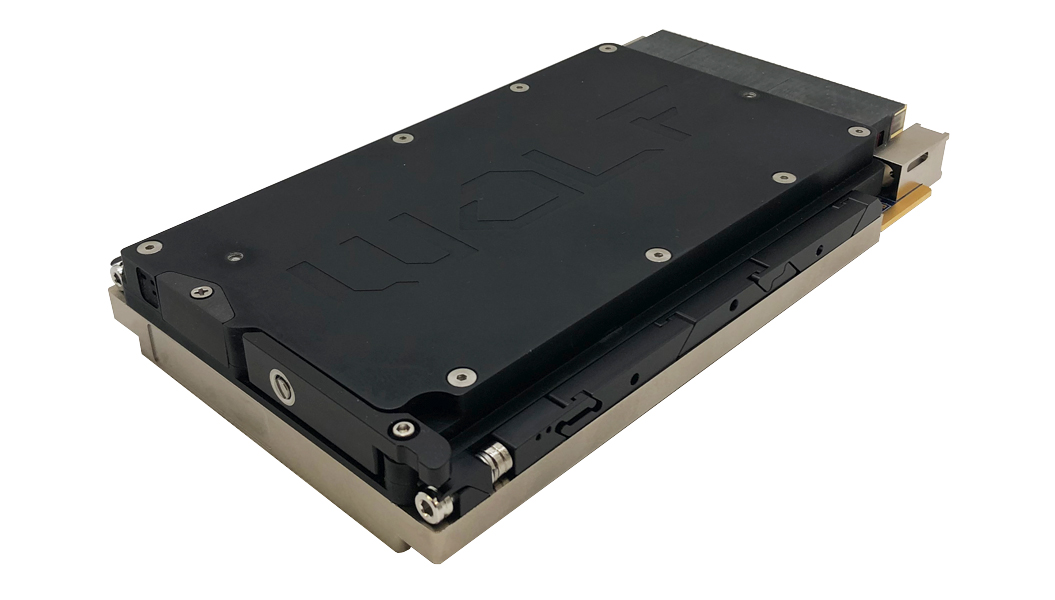

But while the adoption of ATCA into new adjacent markets is a positive, we still believe there are no better solutions to rugged bus structures than VME and OpenVPX (VITA 65). We will continue to support and develop VME-based systems for many years to come.

VME: Which technologies does Emerson offer the defense/critical systems industry today? Some might think of your company more as a telecom provider than a military or critical systems vendor.

DOYLE: We agree that the telecom market is very important for Emerson. Our experience in that market has allowed us to understand the issues of reliability, serviceability, system management, and the need for technical support both before and after sales.

In regard to the military market, Emerson technologies include air-cooled and conduction-cooled extended temperature VME and OpenVPX, ATCA, MicroTCA, COM Express, and CompactPCI. These architectures are being used today in very harsh environments for C4ISR, electronic intelligence, radar, sonar, signals intelligence, electronic warfare, unmanned vehicles, battlefield net-centric communications, and vetronics. We are constantly bringing new ideas to the defense market.

VME: What would you tell industry pundits who are skeptical that ruggedizing MicroTCA would be sufficient for military apps?

DOYLE: The bigger question that most people ask is whether MicroTCA could be a true disruptive technology to architectures such as VME and the new OpenVPX. Our view is that ruggedized MicroTCA will never replace tried-and-true rugged systems, but it can and will fill specific application niches in the military for communication and some edge-computing applications. Having commercial technology available – not just for the economies of scale to decrease product price, but for the actual core building blocks of technologies designed to provide this kind of function – will help its adoption in very important battlefield roles.

VME: Do you predict other telecom form factors stepping up to the military front lines? Which will be most beneficial to defense in the next five years and why?

DOYLE: This is a great question and a topic that we spend an enormous amount of time and effort trying to understand. No one has a crystal ball. But if we start with the conclusion that actionable intelligence is critical and that more decisions will need to be made at the edge, it makes sense that technologies that minimize size, lessen weight, and better utilize power would be optimal. And trade-offs between heat and utilization will be a major focus for the future.

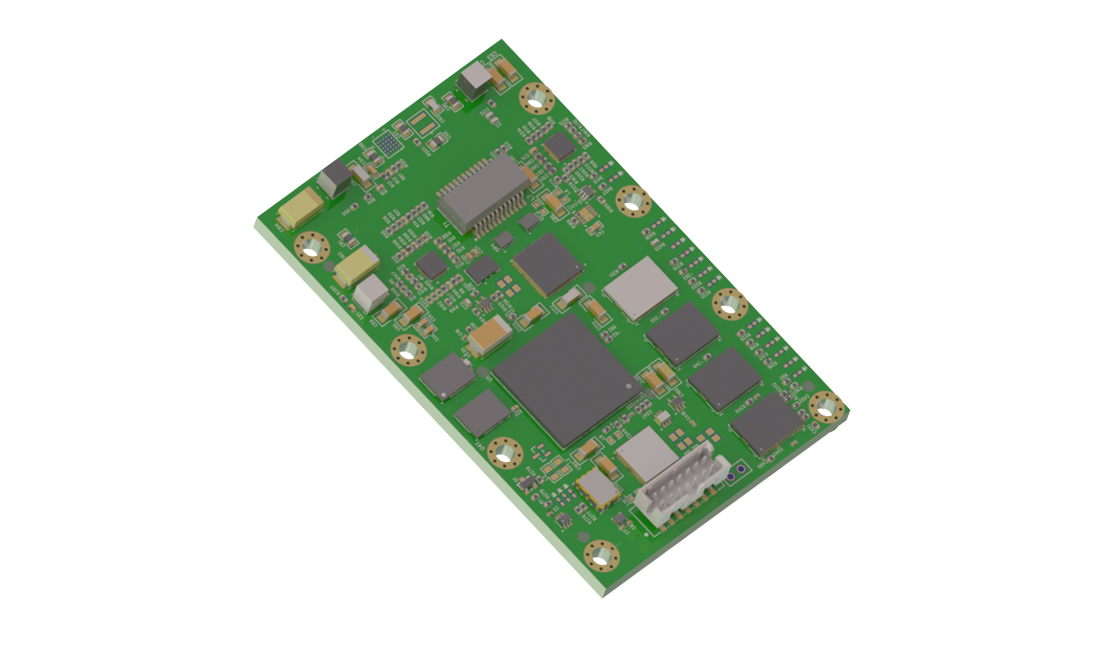

One early adoption form factor making the leap from the telecom space is COM Express, which is inexpensive in comparison to traditional bus architectures; it can perform a variety of tasks at low power with new silicon from Freescale and Intel. And it is a small form factor with a strong ecosystem. UAV designers or program managers working on rugged vehicle displays will definitely want to check out COM Express.

VME: What are the top three technical challenges your customers face, and what is the answer?

DOYLE: The top three technical problems our customers face typically relate to the trade-offs between size, weight, and power. As processing speed and power requirements increase for applications such as UAVs performing ISR missions, every ounce of added weight decreases mission time in the air. Managing trade-offs between these three variables is fundamental to designing a deployable system. Heat and its dissipation are also challenges, not only on the boards but for the total system, coupled with extended temperatures for silicon in harsh operating environments. There are unique ways to cool these boards, but each application comes with its own solution. Not all boards and systems are created equal.

Having said that, the one area I think does not get enough consideration is program risk. I was fortunate to sit with a group of people not too long ago and listen to General James Cartwright, Vice Chairman of the Joint Chiefs of Staff, who said it best: “The military is not a beta test site. We need proven technology in the field that can be rapidly deployed and trusted.” Rigorous testing of boards and systems for thermal, shock, and vibration and being able to provide proven test data directly to branches of the military are key factors in the early adoption of technology.

VME: What do you think will be the most vital power issue to solve within the next decade? How will the industry keep up?

DOYLE: The government has been asking the same question. We are watching several current programs looking for break-through technology that will lessen power-supply weight and increase efficiency to help extend mission times. One of the most interesting concepts I have seen is a power system that uses solar fabrics and methods to recapture the heat dissipated and convert it back into usable energy, thereby getting maximum processing out of small power envelopes.

This is an evolving field. DARPA, for example, recently announced that it is looking for chips for ultra-low-power computing using magnetic states. And, according to their website, their nanostructured materials for power program is exploiting the recent advancements in nano materials to make revolutionary improvements in power applications. If we listen to some of the well-known futurists making predictions based on exponential gains versus linear advancement, then I would say we are not far from finding the answers. I personally don’t see any one silver bullet solving the issue. I believe we need more innovative ideas and talented people working on the problem.

VME: Does Emerson plan on targeting military applications more in the future?

DOYLE: We absolutely will continue to build our defense business. We are committed to developing embedded computing products that provide actionable intelligence to decision makers.

Regarding products, I think it’s pretty certain that very soon the industry can expect to see more announcements about rugged VME, both air- and conduction-cooled, as well as open architecture designs in OpenVPX with extended temperature operating ranges between -40 °C and +85 °C. In addition to traditional bus architectures, there is also a lot of global interest in specific rugged COM Express designs for small form factors, as I mentioned earlier. With the imminent adoption of ATCA in the military and speeds of 40 Gig, we will continue to develop ATCA designs specifically for shipboard and military infrastructure, and we will continue to target rugged C4ISR applications in harsh environments, all while promoting COTS technology.

Embedded Computing, Emerson Network Power 978-761-2951 www.emersonnetworkpower.com/embeddedcomputing